Favorite links

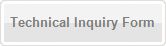

Combination Air Valve, D-025 Compact Series

Drawings Download

Customer drawings are available for registered users only.

If you are registered, please login. If not, please Register.

Configuration Code: GN-LF-NE-MP-ST-PP-OB-SA-CT-RW

- Configuration

- Product Details

- Information

- Complimentary

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Dimension

359 mm (14.13″)

474.5 mm (18.68″)

192 mm (7.56″)

1½″

165 mm (6.5″)

23.5 mm (0.9″)

119.5 mm (4.7″)

4

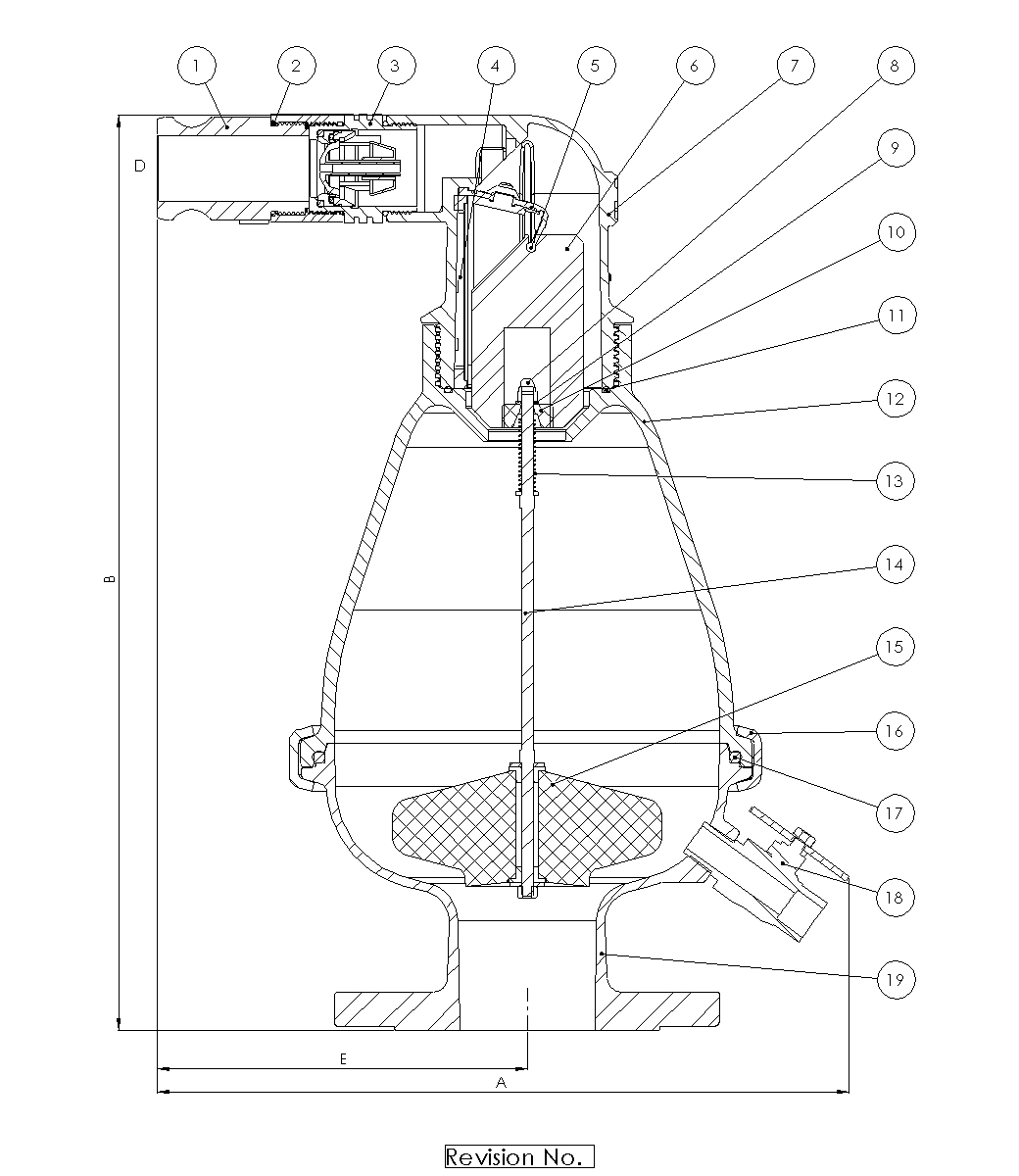

Flange Dimensions

|

Specifications

D025

10 bar (150 psi)

Non Slam

Flange

Multi Std.

2″

60°C (140°F)

18.7 Kg (41.23 Lbs) ±5%

804 mm² (1.25 Sq.in)

12 mm² (0.019 in²)

|

Description The D025 Combination Air Valve combines an air & vacuum orifice and an air release orifice in a single body. The valve is specially designed to operate with liquids carrying solid particles such as wastewater and effluents. The combination air valve discharges air (gases) during the filling or charging of the system, admits air into the system while it is being emptied of liquid and releases accumulated air (gases) from the system while it is under pressure and operating. The valve’s unique design enables the separation of the liquid from the sealing mechanism and assures optimum working conditions. Product Features Specially designed to operate with liquids carrying solid particles such as wastewater and effluents. Unique "air gap" design enables the separation of the liquid from the sealing mechanism and assures optimum working conditions. Combines the features of both an air & vacuum valve and an air release valve. Triple function: Air & vacuum component discharges large volumes of air during filling of the system. Air & vacuum component admits large volumes of air during drainage and at water column separation. The air release component releases entrapped air in pressurized systems. Available 50mm – 100mm (2"4") with a threaded BSP or NPT connection. Available in flange sizes: 50mm – 100mm (2" 4"). These valves are manufactured with flanged ends to meet any requested standard. Materials and Corrosion Protection Valve body is made from composite materials. Operating parts are made of specially selected corrosion resistant polymer materials. Float rod and spring made of stainless steel. Air valve also available in stainless steel and ductile iron. Application Range Working pressure range: 0.210 bar. Maximum operating temperature: 60°C. Maximum intermittent temperature: 90° C. Additional oneway options for air intake/discharge. Install at wastewater & water treatment plants and on wastewater

https://www.youtube.com/watch?v=WCjVyPx4eqY

- Home

- Company Profile

- Products

- Solutions

-

Library

- Articles

- Product Catalogs

- Videos & Animations

- Standards & Approvals

- Recommendations

- Underground Systems Book

- Design Tools

- News & Events

- Contact Us

- Air Valves

- Check Valves

- Agriculture

- Water Supply

- Wastewater

- Industry

- Water Loss Reduction

- Site Map

- A.R.I. Flow Control Accessories Ltd.