Home  Products

Products  Combination Air Valves

Combination Air Valves  High Flow

High Flow  Full Bore Air Valve

D-060/62/65

Full Bore Air Valve

D-060/62/65  Standard Pressure

10 bar – 16 bar

Standard Pressure

10 bar – 16 bar

Products

Products  Combination Air Valves

Combination Air Valves  High Flow

High Flow  Full Bore Air Valve

D-060/62/65

Full Bore Air Valve

D-060/62/65  Standard Pressure

10 bar – 16 bar

Standard Pressure

10 bar – 16 bar

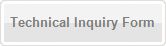

Combination Air Valve, D-060 Series

Drawings Download

Customer drawings are available for registered users only.

If you are registered, please login. If not, please Register.

Product Code: D60SL-EL-P16–02

Configuration Code: A1-XF-YE-Z6-VT-WP-AS-LF-NE-MF-OB-QS-R0-EY

Configuration Code: A1-XF-YE-Z6-VT-WP-AS-LF-NE-MF-OB-QS-R0-EY

- Configuration

- Product Details

- Information

- Complimentary

Flange Standard

Kinetic Valve Body Material

Vent Pipe Adaptor Material

Kinetic Valve Seal Material

Kinetic Valve Seat Material

Kinetic Valve Bolt Set Material

Kinetic Valve Float Material

Automatic Valve Body Material

Automatic Valve Seal Material

Automatic Valve Float Material

O-ring Material

Air Release Outlet

Pressure Release Outlet

Vent Connection Material

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

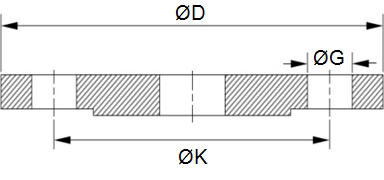

Dimension

217 mm (8.54″)

407 mm (16.03″)

2″ (50mm)

127 mm (5″)

1/8″

6″ (150 mm)

5/8″ (19 mm)

4–3/4″ (120.7 mm)

4

Flange Dimensions

|

Specifications

D060

16 bar (250 psi)

Standard Flow

Flange

ASA 150

2″

Metal

Standard Flow

60°C (140°F)

12 Kg (26.46 Lbs) ±5%

1960 mm² (3.038 Sq.in)

12 mm² (0.019 Sq.in)

|

|

Glossary

|

Description

The D-060 series Combination Air Valve has the features of both an air release valve and an air & vacuum valve. The air release component is designed to automatically release small pockets of air to the atmosphere as they accumulate along a pipeline or piping system when it is full and operating under pressure. The air & vacuum component is designed to automatically discharge or admit large volumes of air during the filling or draining of a pipeline or piping system. This valve will open to relieve negative pressures whenever water column separation occurs.

Main Features

Application Range

|

No complementary products found.

Ari

System by ©

Signature-IT Ltd.

- Home

- Company Profile

- Products

- Solutions

-

Library

- Articles

- Product Catalogs

- Videos & Animations

- Standards & Approvals

- Recommendations

- Underground Systems Book

- Design Tools

- News & Events

- Contact Us

Air Valves | Check Valves | Agriculture | Water Supply | Wastewater | Industry | Water Loss Reduction | Site Map | A.R.I. Flow Control Accessories Ltd.

- Air Valves

- Check Valves

- Agriculture

- Water Supply

- Wastewater

- Industry

- Water Loss Reduction

- Site Map

- A.R.I. Flow Control Accessories Ltd.

scroll table to the right for more